Some Of Sheroz Earthworks

Table of ContentsTop Guidelines Of Sheroz EarthworksThe Basic Principles Of Sheroz Earthworks 7 Easy Facts About Sheroz Earthworks DescribedSheroz Earthworks - An OverviewSheroz Earthworks Can Be Fun For Everyone

For any type of earthwork service provider, it is important to do collaborate with high quality, accuracy, and on timetable. Utilizing machine control in job machines makes it possible for optimizing the various stages in the earthwork procedure, from preparing to the upkeep stage - fj dynamics autosteer review. The maker control system helps the maker driver in achieving the target aircraft swiftly and quicklyThe maker control system overviews the driver with centimeter precision. Remote support conserves time and cash, as it minimizes downtime in jobsites.

Unknown Facts About Sheroz Earthworks

Added training and instructions are always available over remote support when required. The earthmoving sector has utilized our field-proven solutions because the early 1990s. Our system's parts are meticulously developed to stand up to the rough problems of building websites. Comparison of the very same job performed using equipment control versus the standard method discloses that, usually, the conventional technique needs 50% more time to accomplish the same task as the technology-assisted method. https://www.video-bookmark.com/bookmark/6399293/sheroz-earthworks/.

Seems great, best? Go into the Xsite machine control system; it's here to offer you with a considerable advantage when collaborating with earthmoving equipment. Discover just how Xsite Device Control can improve your productivity and ensure job safety and security! We comprehend that finding out a brand-new innovation might seem like a drag, however don't stress! Our pleasant and professional local assistance solutions have obtained you covered, making sure that you can keep functioning smarter without disturbances while on duty! Via remote assistance, your regional Xsite supplier can supply support or troubleshooting without needing to go to the site! What sort of excavators does maker control fit? Xsite Equipment Control systems can be set up to any kind of excavator from mini excavators to large mining excavators.

Just how does machine control work? In 2D systems, the machine is furnished with calibrated disposition sensors.

The system is extremely easy to discover the basics can be instructed in under one hour of training. With Xsite you do not need to bother with learning all the pointers and technique at as soon as. Extra training and instructions are always offered over remote support when required. Get in touch with your regional Xsite dealer to discover out even more! Just how does the remote assistance job? A cordless net connection check this site out makes it possible to develop a remote link in between the device control system and the service.

The Best Guide To Sheroz Earthworks

What sort of data formats Xsite systems support? Xsite Maker Control systems sustain open standard documents layouts, making it possible for smooth information flow from one system to one more. Sustained documents styles: 2D-Maps: DXF Factor documents: DXF, XML, GT, CSV, KOF, PXY Geometry lines: VGP, SBG, XML, Anpakke Surface Area Designs: DXF, XML What parts are set up on my device? Depending on your option of system (with or without placing, i.e - fj dynamics auto steering kit price., 2D or 3D), your device is furnished with inclination sensors, a controller device, and a display/operating panel.

Numerous equipment and software options exist to assist figure out a device's current position on the earth and contrast it with a preferred layout surfaceand building operators can do even more to utilize the advantages. Machine control is using numerous placing sensors and a screen to provide the driver with a referral between the position of the container or blade and the target grade.

Depending upon the arrangement, machine control systems can give the operator with a basic visual guide to pail or blade position, or can instantly relocate the blade to grade by speaking with the device's hydraulics - https://hubpages.com/@sherozau. There are equipment control systems readily available for practically any machine: graders, dozers, excavators, soil and asphalt compactors, scrapers, trimmers, grating equipments, and pavers

5 Easy Facts About Sheroz Earthworks Explained

Some advantages consist of reduced rework, improved work effectiveness, and reduced evaluating costs. Device control can likewise assist enhance performance and lower overall costs. This technology is transforming the method the construction market functions. Building devices without device control will certainly come to be a point of the past and the benefits got from it will be many.

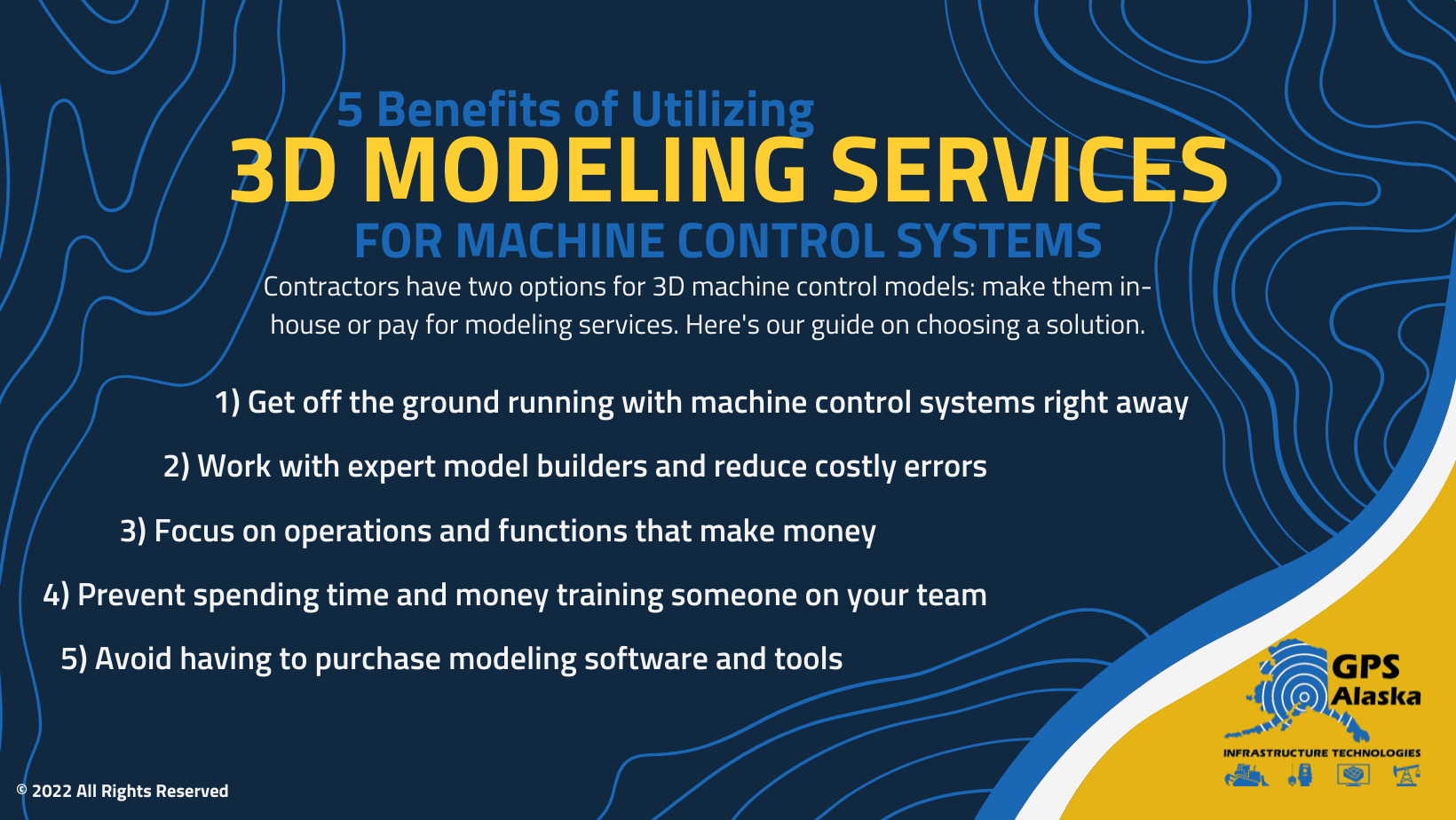

Trimble equipment control systems offer a myriad of benefits to any person that uses earthwork equipment and, at EarthCalc, we can give you with 3D declare your maker control-enable equipment. Not exactly sure if device control deserves the cost? Take into consideration the adhering to reasons that you require to consider this choice.

Making use of GPS lined up with your 3D layout documents, these systems essentially ensure that you will certainly remove or put the correct quantity of product at the construction website. On many construction sites, revamp is a common and discouraging fact, yet with Trimble equipment control, you can remove the requirement for rework.

Rumored Buzz on Sheroz Earthworks

Frequently, with Trimble maker control, you can remove excess tools at a particular work site. As an example, a work that might have needed the use of three or four items of digging deep into tools currently might need just two tools to complete the same task in less time. This enables you to move your equipment to another job website and manage several tasks at once.